Vapour-Tight Tank Rental

PRODUCTION PACKAGES

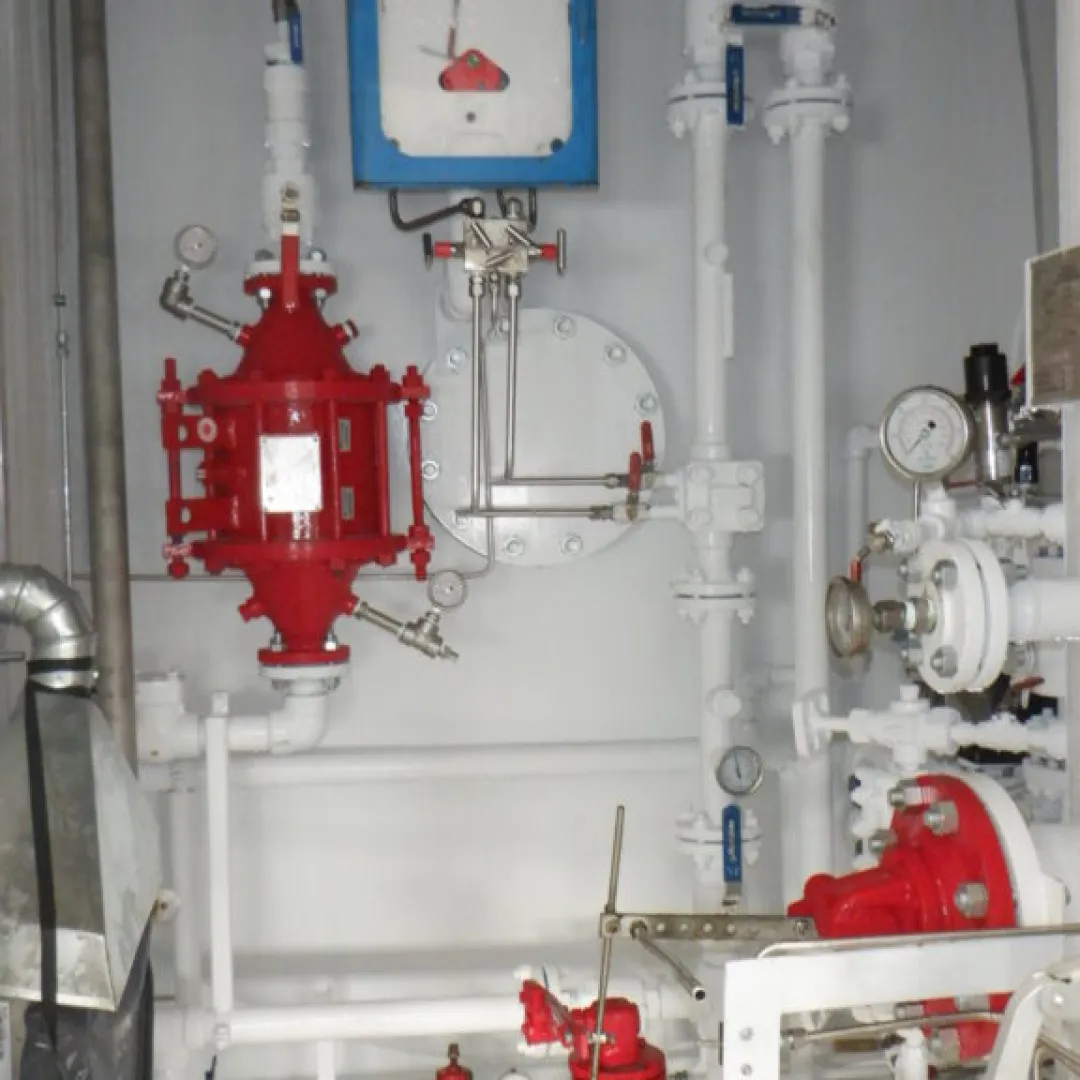

VAPOUR TIGHT TANK PACKAGES

OSY Rental’s Vapour Tight Tank Packages are equipped with all the components necessary to operate a fully functional single well battery, downstream of the wellhead. The set-up of these packages takes roughly four to five hours and consists of these three easy steps: spotting the tank, standing the flare stack and running the flow line and flare line.

Our regular package includes:

Storage – Gas Measurement – Flare Stack – Associated Piping

STORAGE TANK

- 480 to 600 BBL, 14.7 PSI operating pressure

- Internally coated

- All internal piping and projections are standard wall 304SS

- 3” Pressure/Vacuum Pipe Away Relief Vent

- High level and high pressure shutdowns

- Load box

- 2-3” valves with camlocks on load lines

- 3” x 12” planks for under tank skid

FLARE SYSTEM

- 4” x 40’ guyed flare stack

- 3 cement anchor blocks and guy wires

- 3” flame arrestor

- Retractable propane pilot system with regulator and hose

METERING AND CONTROLS

- 2” inlet with 600 ANSI ESD

- 3” SR meter run and 2 pen recorder

- 3” 150# detonation arrestor w/304SS cell

- 3” Kimray backpressure control valve

- 6” x 30” fuel gas scrubber

- Complete piping and instrumentation inside enclosure

- 12” x 24” propane catalytic heater

PIPING

- 200’ of 2” schedule 80 flow line with 2000# hammer unions

- 2” swing

- 160’ of 3” schedule 40 flare line with 1000# hammer unions

- 4- 2” flex lines with hammer unions, 150 ANSI flanges and bolt up kits

- Wood blocks for flow line and flare line

BURNER SYSTEM

- 500,000 BTU burner with fire-tube and chimney

- Profire burner management system

- B149.3 compliant

VAPOUR TIGHT TANK PACKAGE WITH SEPARATOR

OSY Rental’s Vapour Tight Tank Package with Separator come equipped with an inlet separator (ranging from 250 to 1440 PSI) and all the components necessary to operate a fully functional single well battery, downstream of the wellhead. Gas can be flared or pipelined out of the inlet separator while the vapours from the tank are forced to the stack. The set-up of these packages is quick and easy, involving three steps of: spotting the tank, standing the dual flare stack and running the flow line and flare lines.

Our regular package includes:

STORAGE TANK

- 450 to 600 BBL, 14.7 PSI operating pressure

- Internally coated

- All internal piping and projections are standard wall 304SS

- 3” Pressure/Vacuum Pipe Away Relief Vent

- 2” 150# detonation arrestor w/304SS cell

- High level and high pressure shutdowns

- Load box

- 2-3” valves with camlocks on load lines

- 3” x 12” planks for under tank skid

FLARE SYSTEM

- Dual flare stack

- 4” x 40’ guyed flare stack with 2" low pressure riser

- 3 cement anchor blocks and guy wires

- 3” flame arrestor

- Retractable propane pilot system with regulator and hose

METERING AND CONTROLS

- 24” x 5’ sour inlet separator ranging from 250 to 1440 PSI

- 2” inlet with 600 ANSI ESD

- 2” JR meter run w/bypass and 2 pen recorder

- High level shut down and high pressure shutdowns

- 6” x 30” fuel gas scrubber

- Complete piping and instrumentation inside enclosure

- 12” x 24” propane catalytic heater

PIPING

- 200’ of 2” schedule 80 flow line with 2000# hammer unions

- 2” swing

- 320’ of 2” schedule 40 flare line with 1000# hammer unions

- 4- 2” flex lines with hammer unions, 150 ANSI flanges and bolt up kits

- Wood blocks for flow line and flare line

BURNER SYSTEM

- 500,000 BTU burner with fire-tube and chimney

- Profire burner management system

- B149.3 compliant