Rent 3 phase separators – New or Used (Refurbished) Oil & Gas Separators

We have a huge stock of oil & gas separators from various manufacturers in almost any size or pressure range you will need. The separators are reliable, quality checked, refurbished, and ready to go. OSY Rentals will bring your separator out to any site in Western Canada. Contact us to save your capital expenditures.

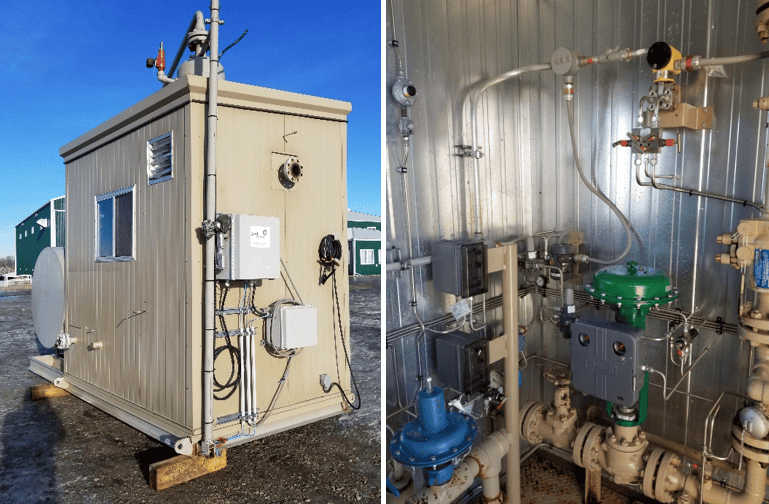

Rent 3 phase separator with custom outfitting and mounted on trailers

We have separators outfitted in various ways. Chances are good that we have the new or reconditioned separators you need in stock, but if we don’t, we can perform custom modifications or get what you need quickly.

Available sizes:

- 16” x 7’ 6”

- 24” x 7’ 6”

- 30” x 10’

- 36” x 10’

Available pressure ranges:

- 250-1440 PSI

We carry separators from:

- Stettler Oil & Gas

- Foremost

- Ultrafab

- Argo

- Boomers

- RJV

- Aspire

Rent, rent to own, and purchase plans available for oil gas separators rental

Our payment options are very flexible. You can rent your separator and choose to purchase it later with a portion of your rental going towards the cost, buy it outright, or just rent it. Whatever works best for your business.

Why to rent 3-phase Oil gas separators from OSY Rentals?

OSY Rentals is dedicated solely to oil & gas equipment rental and installation. We aren’t a massive international giant that doesn’t know the local landscape in Western Canada – this is where we live and this is where we work. We know all the regulatory requirements, pitfalls of specific areas, and all the other small details that can make a difference when you are in a rush. We believe in getting your job done quickly, but quality is never sacrificed for meeting a deadline.

Oil gas separators rent cost

We have separators outfitted in various ways. Chances are good that we have the new or reconditioned separators you need in stock, but if we don’t, we can perform custom modifications or get what you need quickly.

How to size a three-phase separator?

To size a three-phase separator the key steps are:

- Gather the required data, including oil rate, water rate, gas rate, operating pressure and temperature, fluid properties (density, viscosity), and desired droplet size removal targets.

- Determine the appropriate retention times for the oil and water phases. Common ranges are 3-30 minutes for oil and 10 minutes for water.

- Calculate the necessary vessel diameter and length/height based on the fluid flow rates, desired retention times, and droplet size targets. This involves using equations and correlations to size the gas, oil, and water sections of the separator.

- Select the appropriate separator configuration, such as horizontal with a weir or horizontal with an oil bucket and weir.

Incorporate the necessary internals, such as an inlet device, mist extractor, weir plate, and sand jetting system.

Specify the material of construction and any corrosion allowance.

The overall goal is to design a separator that will effectively separate the gas, oil, and water phases while meeting the process requirements and being cost-effective.

The detailed calculations and design considerations are outlined in references such as the GPSA Engineering Databook and Surface Production Operations by Arnold and Stewart. (Buy online at Amazon).

This site might help in calculations regarding size of three phase separators – https://sites.google.com/site/sizingwizards/

What are the different types of 3-phase separators?

There are several types of three-phase separators used in the oil and gas industry:

Horizontal Three-Phase Separators

Horizontal three-phase separator with overflow weir: The fluid enters the vessel and hits an inlet diverter, causing initial gas-liquid separation. The oil forms a layer above the water, with the interface level controlled by a dump valve. The oil spills over a weir and the water exits under the weir.

Horizontal three-phase separator with oil bucket and water weir: Similar to the overflow weir design, but the oil collects in a bucket instead of spilling over a weir. The oil and water levels are controlled independently by separate dump valves.

Horizontal three-phase separator with boot design: Includes a water “boot” at the bottom to collect small amounts of settled water. The oil and water retention times are designed to allow separation without using the main vessel.

Vertical Three-Phase Separators

Vertical three-phase separator with interface control: The fluid enters and hits an inlet diverter to separate bulk gas. A downcomer routes the liquid through the oil-water interface. Separate dump valves control the oil and water levels.

Vertical three-phase separator with downcomer and spreader: Similar to the interface control design, but includes a spreader to water-wash the incoming stream.

Other Types of 3 Phase Separators

Spherical three-phase separator: Used to remove free water to avoid emulsions, hydrates, and corrosion. Has limited surge capacity.

Free-water knockout (FWKO): Processes a liquid stream with little gas. In a 3-phase FWKO, the oil, water, and gas are separated in the same vessel.

The choice of horizontal, vertical, or spherical configuration depends on factors like gas handling requirements, space constraints, and solid handling needs. Proper design is critical to ensure efficient phase separation and mitigate operating problems.

How do you calculate the retention time of a 3-phase separator?

To calculate the retention time of a three-phase separator:

- Determine the required retention times for the oil and water phases. Common guidelines are:

- Oil retention time: 3-30 minutes

- Water retention time: 10-30 minutes

- Calculate the oil and water retention times based on the vessel dimensions and fluid flow rates:

- Oil retention time = Oil liquid level / Oil volumetric flow rate

- Water retention time = Water liquid level / Water volumetric flow rate

For example, if the oil liquid level is 1 ft and the oil flow rate is 5.10 ft³/min, the oil retention time would be 16.8 minutes .

- Ensure the calculated retention times meet the recommended guidelines from step 1. Adjust the vessel size or flow rates if needed to achieve the target retention times.

- The gas retention time is typically not a critical design parameter, as the gas phase separates quickly. However, it should be checked to ensure adequate gas-liquid disengagement.

The key is to size the three-phase separator to provide sufficient residence time for the oil and water phases to separate effectively, based on the fluid properties and flow rates. Proper retention time is crucial for achieving good phase separation performance.

More details can be seen in this pdf file.

OSY Rentals is your go-to source among oilfield rental companies in Alberta for reliable equipment and installation services. Contact us today to discuss your project requirements and discover how we can help you save time and reduce your capital expenses by renting oilfield equipment in Alberta.